No products in the cart.

TECHNICAL SPECIFICATIONS

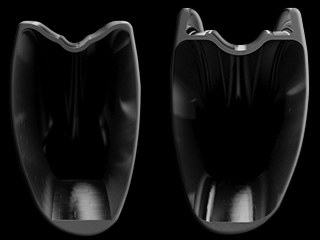

| 650B 38mm disc brake bike carbon rims, DH / EBIKE symmetric tubeless bicycle rims | |

| Model | RSD738DH |

| Weight | 530±15g |

| ERD | 545mm |

| Material | T700 + T800 |

| Terrain | DH | EBIKE |

| REC.Tire Size | 27.5*2.5~2.8" |

| Manual Specification: | |

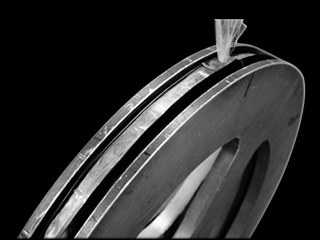

| External Nipple Hole | 4.5 mm |

| Internal Nipple Hole | 2.5 mm |

| Nipple Hole Thickness | 3.0 mm |

| Valve Hole | 6.5 mm |

| Brake Type | Disc Brake |

| Tire Bead | Hookless |

| Tire Type | Tubeless |

| 27.5er MTB Rim Finish | UD / 3K |

| REC Tire Pressure | 25~30 PSI |

| Max Spoke Tension | 140 kgf |

| Max Rider Weight | 150kg |

| Service + Delivery: | |

| From Germany to European countries | |

| From China to Asia & America | |