No products in the cart.

TECHNICAL SPECIFICATIONS

| Series | 206SP 700c Carbon Road Bike Disc Brake Wheelset |

| Model | 206DB-RBD50C |

| Weight | 1495g ( ±5% ) |

| Brake Type | Disc Brake |

| Tire Type | Clincher | TLR |

| Applied Terrain | Road |

| Recommended Tire Pressure | 100 psi |

| REC.Tire Size | 700*28~45C |

| Max Rider’s Weight | 130 kgs |

| More Manual Specifications: | |

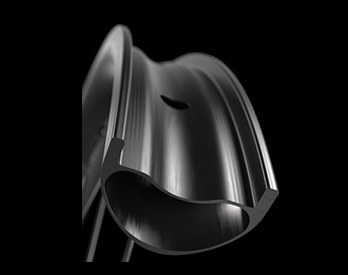

| Rims | RBD50C Arch Bridge Series |

| Toray T700 & T800 Full Carbon Fiber | |

| 50mm Height | 23mm IW | 30mm OW | |

| Road Clincher | TLR | |

| Hubs | Black straight pull center lock disc brake hubs, Enduro bearings, RATCHET 36T SL |

| Thru axle version 12*100mm front | 12*142mm rear | |

| Front hub 24 holes, rear hub 24 holes | |

| Shimano 11s HG or Sram XDR cassette body | |

| Spokes | WING20, black |

| Nipples | AC18/AC14, black |

| Warranty | 2 years manufacturing failure for wheel components |

| Crash replacement | 2 years with 10% off on the rims |

| Wheel Building Technology: | |

| All wheels are 100% built by well-trained technicians and trued under EN standard. | |

| The perfect allocation of spoke tension in every single spoke in combination with a comparatively high spoke tension gives many advantages: | |

| – Higher radial, lateral and torsional stiffness | |

| – Less spoke tension loss over time | |

| – Longer durability | |

| – Fewer maintenance efforts like re-truing | |

| Wheel Accuracy: | |

| – Wheel roundness tolerance: ≤0.3mm | |

| – Wheel lateral tolerance: ≤0.3mm | |

| – Wheel center tolerance: ≤0.3mm | |

| Service + Delivery: | |

| From Germany to European countries | |

| From From China to Asia & America | |