No products in the cart.

TECHNICAL SPECIFICATIONS

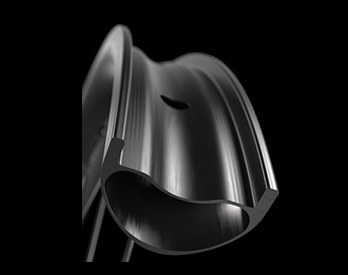

| MODEL | FAT26-85S |

| Weight | 2147g+/-5% |

| Rim Depth | 22mm |

| Rim Inner width | 80mm |

| Rim Edge width | 85mm |

| Tire Type | Tubeless, Clincher |

| Material | T700 Toray Full Carbon Fiber |

| Rim Finish | UD |

| Applied Terrain | Snowbike/Fatbike |

| Manual Specification: | |

| Hubs | -Chosen J Bend Pull -Front 12×135 or 12 x 150mm thru axle, 6 bolts, 32 holes -Rear 12×177 or 12 x 197mm thru axle, 6 bolts, 32 holes -Shimano 11s or Sram XD cassette body |

| Spokes | Pillar 1423, black |

| Nipples | Sapim alu nipples, black |

| Warranty | 2 years manufacturing failure for wheel components |

| Recommended Rider's Weight | 110-130 kg |

| Crash replacement | 2 years with 10% off on the rims |

| Wheel Building Technology: All wheels are built-in high precision machines via spoke tension truing by Holland Mechanics Pro Truer. The perfect allocation of spoke tension in every single spoke in combination with a comparatively high spoke tension gives many advantages: -higher radial, lateral and torsional stiffness -less spoke tension loss over time -longer durability -fewer maintenance efforts like re-truing Wheel Accuracy: -Wheel roundness tolerance: ≤0.3mm -Wheel lateral tolerance: ≤0.3mm -Wheel center tolerance: ≤0.3mm |

|

| Service + Delivery: | |

| From Germany to European countries | |

| From From China to Asia & America | |